When using a Fully Automatic CNC Machine, the following aspects should be considered

The Fully Automatic CNC Machine development process can be implemented by all enterprises simultaneously through the efficient execution of the workpiece machining program. Therefore, the advantages and disadvantages of machining application programming analysis can be selected to directly affect the final machining accuracy and efficiency of the workpiece. The premise of the workpiece processing system programming is to determine the process arrangement, and the manufacturer should consider the following aspects when talking about Fully Automatic CNC Machine:

The shape and position accuracy requirements of the Fully Automatic CNC Machine: the shape and position tolerance given on the part pattern is an important basis for ensuring the accuracy of the part. When processing, it is necessary to determine the position and measurement standards according to its requirements, and to process some technologies according to the special needs of a Fully Automatic CNC Machine to effectively control the accuracy of the shape and position.

Second, material and heat treatment requirements: the material and heat treatment requirements given on the part drawing are the basis for selecting the type of tool and Fully Automatic CNC Machine and determining the cutting amount.

Surface roughness requirements: Surface roughness is an important requirement to ensure the microscopic accuracy of the surface of the part, and it is also the basis for reasonable selection of Fully Automatic CNC Machine, cutting tools and determining cutting parameters.

Dimensional accuracy requirements of Fully Automatic CNC Machine: Analyze the dimensional accuracy requirements of parts drawings, determine whether the enterprise can effectively use the turning process to achieve, and determine the process research method of risk control dimensional accuracy. In the process of analyzing and developing this work, students can also learn some basic dimensional transformations, such as incremental dimensions and dimensions and dimensional chain calculations.

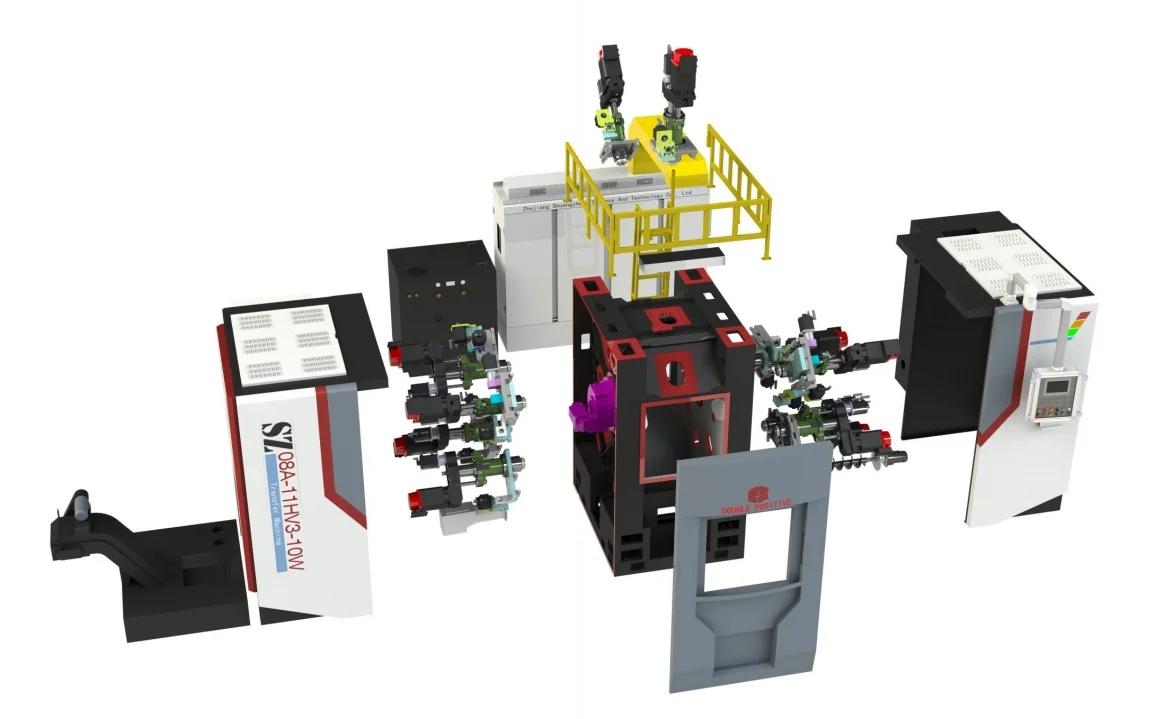

Fully Automatic CNC Machine is a composite machining machine, which can not only be turned, but also be boring. When there is a plane and a hole on the workpiece to be processed at the same time, the plane should be first turned and then boring, because the cutting force is large when rotating the plane, the workpiece is easy to deform, the first turning and then turning and boring, so that it can be restored for a period of time, which is conducive to the recovery of the deformation after boring, ensuring the machining accuracy of the hole.

Fully Automatic CNC Machine https://www.zjshuangzheng.com/Fully-Automatic-CNC-Machine-Category